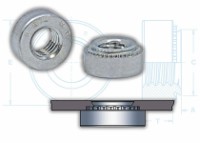

NEW PEM® S-RT™ SELF-CLINCHING FREE-RUNNING LOCKNUTS WITH MODIFIED THREADS ENABLE EASIER TIGHTENING OF MATING SCREWS AND VIBRATION-RESISTANT LOCKING PERFORMANCE

New PEM® S-RT™ self-clinching free-running locknuts from PennEngineering® feature a modified thread angle enabling easier tightening of mating screws and superior vibration-resistant locking performance in thin metal assemblies. The modified thread formation allows mating screws to spin freely during the attachment process until clamp load is induced during the screw-tightening process.

The applied clamp load then engages the locknut’s vibration-resistant locking feature, which securely and reliably locks the screw in place. Compared with traditional locknuts, excellent joint clamp load remains consistent, even after many on/off cycles.

PEM S-RT self-clinching locknuts install into aluminum or steel sheets as thin as .030”/0.8mm and become permanent parts of an assembly. Upon their installation using a PEMSERTER®or other standard press, the back side of the host metal sheet for screw insertion will be flush or sub-flush and the assembly side will be flush or sub-flush ideally suiting sheet-to-sheet attachment applications.

These carbon steel locknuts can be specified with thread sizes from #4-40 through 5/16-18 and M3 through M6 and in a variety of shank lengths. Zinc plating finishes are available in standard colorless or optional yellow.

Detailed technical literature (PEM® Bulletin RT), individual fastener drawings, and CAD models for these RoHS-compliant fasteners can be downloaded at www.pemnet.com.

Founded in 1942 and celebrating 75 years, PennEngineering (Danboro, PA, USA) is a global leader in the fastening industry with technical and manufacturing facilities in North America, Europe, and Asia supported by a global engineering-focused sales force and a worldwide network of authorized distributors.